Un nouveau réseau de distribution

Fruit de notre alliance avec le groupe Beretta, nous sommes heureux d’officialiser notre nouveau réseau de distribution mondial avec les 14 principales filliales étrangères

For over a century, the Chapuis gunsmiths have been innovating and evolving to design and manufacture top-quality weapons. Today, technology is at the service of art and tradition to enable us to create and produce unique weapons with unequalled finishes.

Over the years, the process of making a weapon has evolved considerably. In the past, master gunsmiths had to base their designs on 2D drawings. They then had to use materials that were easy to shape and machine, such as wood, to create models and test the various parts that made up their weapons. It was a process that required a great deal of time and expertise, and was not always very precise.

Today, thanks to 3D design, our teams are able to create the entire design and mechanism of a weapon with great precision.

Each model is born of a new idea, a challenge to be met. Imagining an original finish, working with a different material, studying a new mechanism, to create a unique weapon.

Our teams then bring this idea to life by making the first sketches using SolidWork software, a benchmark in 3D design.

This enables us to design and draw the entire mechanism and the external shapes of the parts that will make up the weapon. All the parts are then assembled, and the kinematics virtually tested before a prototype is built.

SolidWork enables the weapon’s parts and mechanisms to be tested easily and accurately. We can carry out mechanical simulations to check the kinematics, make sure there are no collisions, and also measure the stress that each part has to withstand.

This is an essential stage in the manufacturing process, because the stress on the parts is linked to the function they will have in the weapon.

The materials chosen must therefore be suitable for absorbing the repeated shocks of the pressure build-up that the weapon has to withstand each time it is fired.

The software allows us to directly modify the materials used to ensure that they are fit for purpose.

Once the functional part is complete, we can then work on the surface of the parts to achieve an aesthetic finish in line with the expected final result.

After several simulations, and once the mechanism is perfectly functional, our teams create 2D drawings, with dimensions and machining tolerances, so that each part can be machined and assembled.

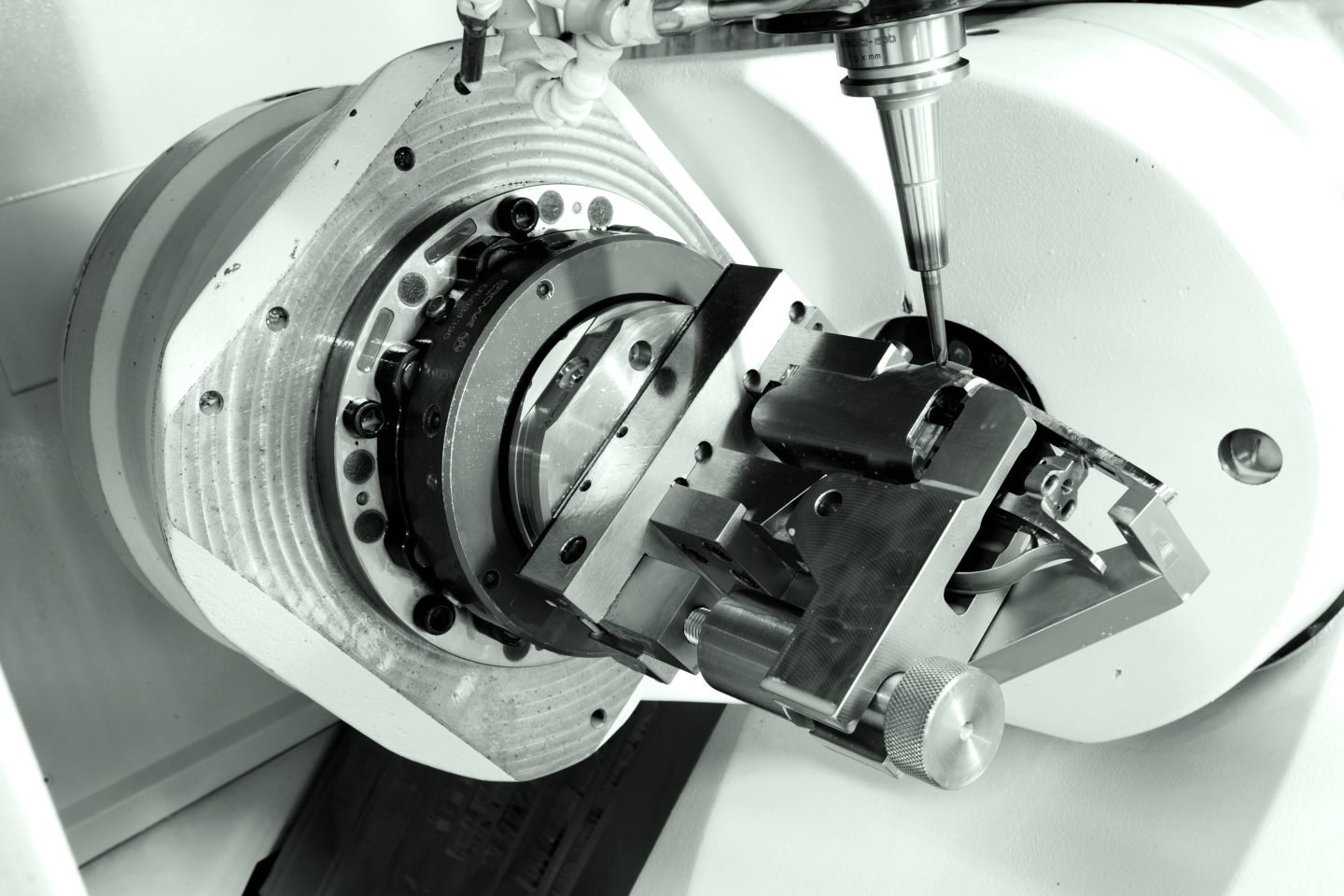

The plans and parts drawn in the software can then be exported directly to the machining centres. The manufacturing process is therefore much faster and more accurate.

Our machines are programmed using the software’s drawings, which minimises the risk of error and produces parts with ultra-precise dimensions.

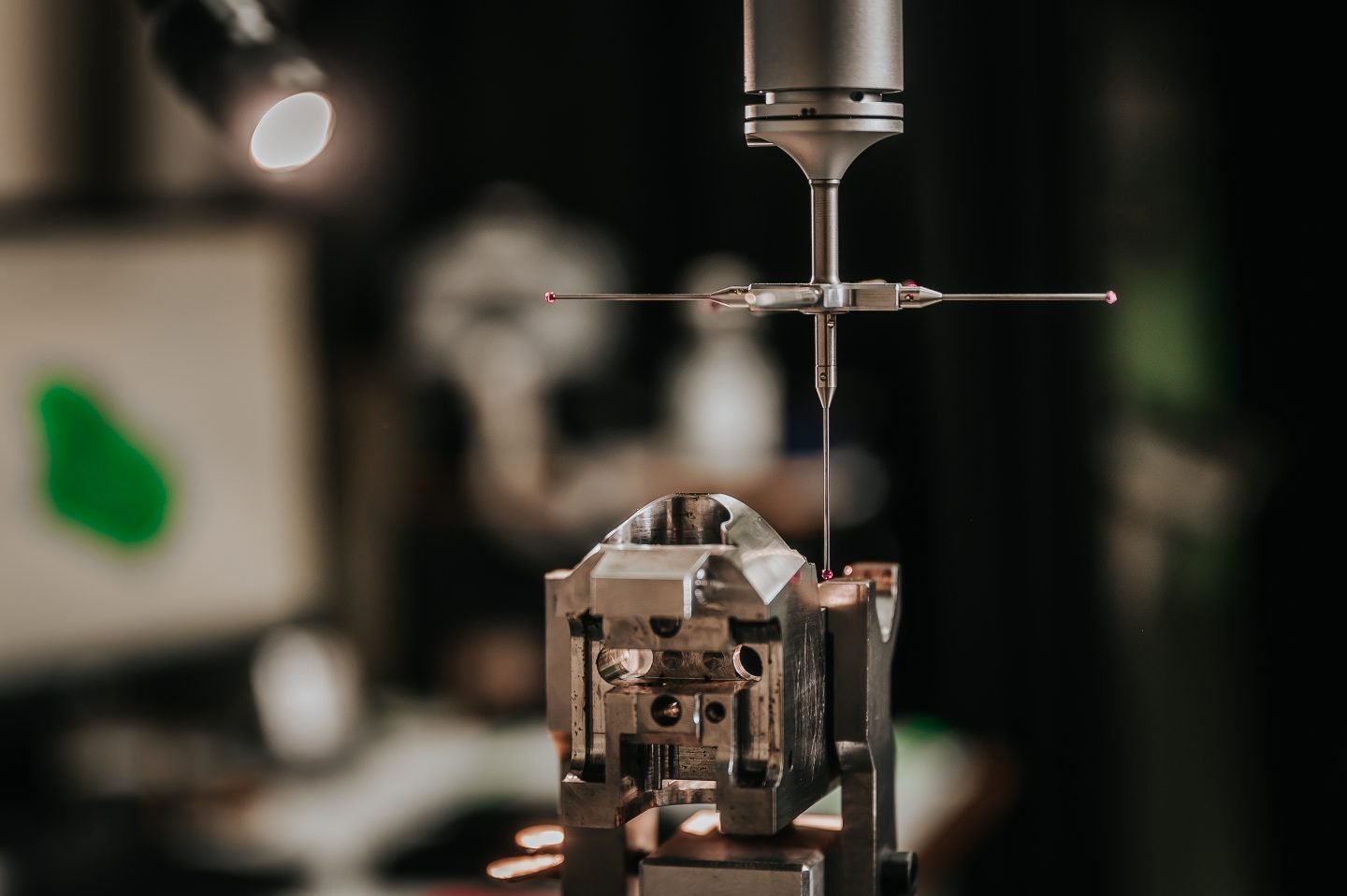

The manufactured parts are then checked by a three-dimensional inspection machine to ensure conformity.

Finally, the parts are assembled by the expert hands of our master gunsmiths to produce an exceptional weapon with ideal performance and high-quality finishes.

All the 3D and 2D drawings of our guns are saved and can easily be re-used. Our teams can modify an existing weapon model by reusing and developing the original plans to improve the weapon’s performance over time.

Fruit de notre alliance avec le groupe Beretta, nous sommes heureux d’officialiser notre nouveau réseau de distribution mondial avec les 14 principales filliales étrangères

Fruit de notre alliance avec le groupe Beretta, nous sommes heureux d’officialiser notre nouveau réseau de distribution mondial avec les 14 principales filliales étrangères

Fruit de notre alliance avec le groupe Beretta, nous sommes heureux d’officialiser notre nouveau réseau de distribution mondial avec les 14 principales filliales étrangères

Fruit de notre alliance avec le groupe Beretta, nous sommes heureux d’officialiser notre nouveau réseau de distribution mondial avec les 14 principales filliales étrangères

Fruit de notre alliance avec le groupe Beretta, nous sommes heureux d’officialiser notre nouveau réseau de distribution mondial avec les 14 principales filliales étrangères